Axial Flux Motors Calculations

11. Easy Motor Math (No Scary Formulas!)

Let me explain this like you're learning to drive - we'll start with the basics and build up!

The Pizza Analogy - Understanding Motor Size vs Power

graph LR

subgraph "Pizza Analogy"

A[Regular Pizza = Radial Motor] --> A1[Round + Thick]

B[Thin Crust Pizza = Axial Motor] --> B1[Wide + Flat]

end

subgraph "Power Scaling"

C[Radial: Area = πr²] --> C1[Power ∝ D²]

D[Axial: Volume = πr²h] --> D1[Power ∝ D³]

endThink of motors like pizzas:

- Radial flux motor = Regular pizza (round, but thick)

- Axial flux motor = Thin crust pizza (wide and flat)

Activity 1: Same Energy In, Different Results Out

The Setup: Imagine you have 10 units of electrical energy to feed into both motors. Both motors are initially the same size (like two 12-inch pizzas).

What Happens When We Make Them Bigger?

Radial Flux Motor (Regular Pizza)

Think of this like making a pizza both wider AND thicker:

Step 1: Start with basics

- Energy in:

units - Efficiency:

= 92% (loses 8% as heat, like a leaky bucket) - Energy out:

units

Step 2: Make it bigger (from 200mm to 300mm diameter)

- This is like going from 12-inch pizza to 18-inch pizza

- Size increase ratio:

(it's 1.5 times bigger) - But power grows with AREA:

Step 3: Reality check

- The bigger motor COULD handle:

units - But we're still only feeding it 10 units of energy

- So output stays at 9.2 units (we're not using its full potential)

Axial Flux Motor (Thin Crust Pizza)

This one gets stronger in a weird way - like a pizza that gets more powerful the wider you make it:

Step 1: Start with basics

- Energy in:

units - Efficiency:

= 94% (slightly less leaky bucket) - Energy out:

units

Step 2: Make it bigger (same size increase)

- Same

times bigger in diameter - But axial flux grows with VOLUME:

Step 3: Reality check

- The bigger motor COULD handle:

units - But again, only fed 10 units

- Output: 9.4 units (but WAY more potential)

🧠 Brain Food: Both motors give similar output NOW, but the axial flux has way more room to grow!

Activity 2: Same Output Needed, Different Energy Required

The Setup: Both motors need to produce exactly 25 units of mechanical power (like both need to lift the same heavy box).

The Water Tank Analogy

graph TD

A[Energy Input] --> B[Water Tank with Holes]

B --> C[Useful Output]

B --> D[Wasted Energy - Holes]graph TD

E[Better Efficiency = Smaller Holes]

F[Worse Efficiency = Bigger Holes]Think of efficiency like water tanks with holes:

- Better efficiency = smaller holes = less waste

- Worse efficiency = bigger holes = more waste

Radial Flux Motor (Regular Tank)

Step 1: How much energy do we need to pour in?

- Efficiency:

= 93% (loses 7% through the holes) - To get 25 units out:

units

Step 2: Where does the extra 1.9 units go?

units lost as heat in wires (like friction) units lost in iron core (magnetic losses) units lost to mechanical friction units just... disappears (stray losses)

Axial Flux Motor (Better Tank)

Step 1: How much energy needed?

- Efficiency:

= 95.5% (smaller holes, less waste!) - To get 25 units out:

units

Step 2: Why is it more efficient?

- Shorter wires = less heat loss (like shorter garden hose = less pressure loss)

- Better cooling = flat surface cools better (like pancake vs meatball)

- Smarter magnetic design = less wasted magnetic energy

Step 3: Where does the 1.2 units go?

units in wires (less because shorter) units in iron (less because better design) units mechanical (less friction) units stray losses

The Money Talk

Savings per year: $$\Delta P = 26.9 - 26.2 = 0.7 \text{ units less needed}$$

If electricity costs 10 rupees per unit and you run it 10 hours/day for a year:

The "Aha!" Moment Examples

Example 1: The Bicycle Wheel

graph LR

subgraph "Torque Analogy"

A[Same Force Applied] --> B{Where Applied?}

B --> C[Near Hub - Less Torque]

B --> D[At Rim - More Torque]

endTorque Energy (τ) = Radius (r) × Force (F)

Imagine spinning two wheels with the same force:

- Radial motor = Like pedaling a regular bike wheel

- Axial motor = Like spinning a frisbee - more "leverage" at the edge

Why axial is stronger: The further out you apply force on a spinning disc, the more torque you get!

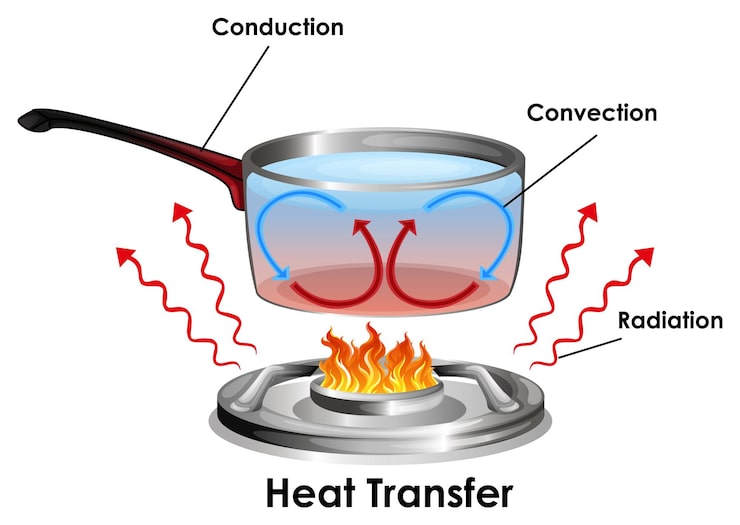

Example 2: The Campfire

graph LR

A[Heat Source] --> B{Shape}

B --> C[Log - Trapped Heat]

B --> D[Pancake - Heat Escapes]Cooling comparison:

- Radial motor = Like a log in a fire (heat trapped inside)

- Axial motor = Like a flat pancake on a grill (heat escapes from both flat sides)

Better cooling = higher efficiency = less energy wasted!

Heat transfer:

Practice Time (Easy Mode)

Problem: The Scaling Challenge

A small radial motor makes 5 units of power with 150mm diameter. If we make it bigger to 250mm diameter:

Step 1: Find the size multiplier $$k = \frac{D_{new}}{D_{old}} = \frac{250}{150} = 1.67 \approx 1.7 \text{ times bigger}$$

Step 2: Calculate new power

- Radial motor: Power grows with area =

times stronger - New power =

units

Step 3: What if it was axial flux?

- Axial grows with volume =

times stronger - New power =

units

🎯 Key Insight: Bigger diameter helps axial flux WAY more than radial flux!

Mathematical Summary: $$P_{radial} \propto D^2 \quad \text{vs} \quad P_{axial} \propto D^3$$

The Bottom Line (TL;DR)

mindmap

root((Motor Choice))

Radial Flux

Like Toyota Camry

Reliable & Cheap

Easy Manufacturing

Good for Small-Medium

Axial Flux

Like Tesla

High Performance

Better Efficiency

Great for Large Diameter

Key Formulas

Radial: P ∝ D²

Axial: P ∝ D³

Efficiency η = Pout/PinThink of it like this:

- Radial flux = Reliable, like a Toyota Camry - does the job, everyone knows how to fix it

- Axial flux = High-performance, like a Tesla - more efficient, better for specific jobs, but costs more

When to choose what:

- Need it cheap and simple? → Radial flux

- Need maximum power in small space? → Axial flux

- Going big (like wind turbines)? → Definitely axial flux

- Making thousands of them? → Probably radial flux (easier manufacturing)

Math made simple:

- Bigger diameter helps both, but helps axial flux MORE

- Axial flux wastes less energy (2-4% more efficient)

- For same job, axial flux needs slightly less electricity

Key Scaling Relationships:

- Radial flux:

where - Axial flux:

Remember: You don't need to be a math genius - just understand the concepts and the patterns!

12. Quick Reference Formulas

Power and Torque

13. Troubleshooting Guide

Common Issues and Solutions

| Problem | Likely Cause | Radial Flux Solution | Axial Flux Solution |

|---|---|---|---|

| Low Efficiency | High resistance | Check winding connections | Verify PCB winding integrity |

| Overheating | Poor cooling | Improve ventilation | Check surface contamination |

| Vibration | Unbalanced rotor | Standard balancing | Disc flatness check |

| Low Torque | Air gap too large | Adjust concentricity | Check axial positioning |

14. Key Takeaway

The choice between axial and radial flux motors depends on specific application requirements. Radial flux offers maturity and cost-effectiveness, while axial flux provides superior power density and form factor advantages, particularly in larger diameter applications. The calculation activities demonstrate that axial flux motors typically offer 2-4% higher efficiency and significantly better scaling characteristics for larger sizes.